GRAPHITE 6

COMMERCIAL GRAPHITE

CARBON PRODUCTS

Carbon products are obtained by heating coal (to give coke), natural gas (to give blacks), or carbonaceous material of vegetable or animal origin, such as wood or bone (to give charcoal), at elevated temperatures in the presence of insufficient oxygen to allow combustion. The volatile by-products are recovered and used separately.

EDWARD G. ACHESON

Graphite was first synthesized accidentally by Edward G. Acheson while he was performing high-temperature experiments on carborundum. He found that at about 4,150 °C (7,500 °F) the silicon in the carborundum vaporized, leaving the carbon behind in graphitic form. Acheson was granted a patent for graphite manufacture in 1896, and commercial production started in 1897. Since 1918 petroleum coke, small and imperfect graphite crystals surrounded by organic compounds, has been the major raw material in the production of 99 to 99.5 percent pure graphite.

BLACK LEAD

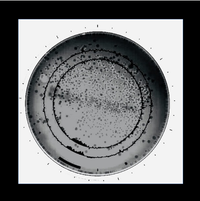

Graphite, also called plumbago or black lead, mineral consisting of carbon. Graphite has a layered structure that consists of rings of six carbon atoms arranged in widely spaced horizontal sheets. Graphite thus crystallizes in the hexagonal system, in contrast to the same element crystallizing in the octahedral or tetrahedral system as diamond. Such dimorphous pairs usually are rather similar in their physical properties, but not so in this case.

DARK GRAY

Graphite is dark gray to black, opaque, and very soft (with a hardness of 1 1/2 on the Mohs scale), while diamond may be colourless and transparent and is the hardest naturally occurring substance. Graphite has a greasy feel and leaves a black mark, thus the name from the Greek verb graphein, “to write.” For detailed physical properties of graphite, see native element.

THE METAMORPHOSIS OF SEDIMENTS

Graphite is formed by the metamorphosis of sediments containing carbonaceous material, by the reaction of carbon compounds with hydrothermal solutions or magmatic fluids, or possibly by the crystallization of magmatic carbon. It occurs as isolated scales, large masses, or veins in older crystalline rocks, gneiss, schist, quartzite, and marble and also in granites, pegmatites, and carbonaceous clay slates. Small isometric crystals of graphitic carbon (possibly pseudomorphs after diamond) found in meteoritic iron are called cliftonite.

GRAPHITE PENCILS

Graphite or lead pencil is a writing, drawing or drawing tool in which a thin graphite core is embedded in a shell of other material. The pencil shell is mostly wooden, but can be made of plastic or recycled paper.

SOLID LUBRICANT

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

DRY LUBRICANTS

The two main dry lubricants are graphite and molybdenum disulfide. They offer lubrication at temperatures higher than liquid and oil-based lubricants operate. Dry lubricants are often used in applications such as locks or dry lubricated bearings.

350°C

Such materials can operate up to 350 °C (662 °F) in oxidizing environments and even higher in reducing / non-oxidizing environments (molybdenum disulfide up to 1100 °C, 2012 °F). The low-friction characteristics of most dry lubricants are attributed to a layered structure on the molecular level with weak bonding between layers. Such layers are able to slide relative to each other with minimal applied force, thus giving them their low friction properties.

POLYCYCLICS CARBON ATMOS

Graphite is structurally composed of planes of polycyclic carbon atoms that are hexagonal in orientation. The distance of carbon atoms between planes is longer and, therefore, the bonding is weaker.

IN VACUUM

Graphite is best suited for lubrication in air. Water vapor is a necessary component for graphite lubrication. The adsorption of water reduces the bonding energy between the hexagonal planes of the graphite to a lower level than the adhesion energy between a substrate and the graphite. Because water vapor is a requirement for lubrication, graphite is not effective in vacuum.

GALVANIC CORROSION

Because it is electrically conductive, graphite can promote galvanic corrosion. In an oxidative atmosphere, graphite is effective at high temperatures up to 450 °C continuously and can withstand much higher temperature peaks.

GRAPHITE CRUCIBLES

A crucible is a container used to hold metal for melting in a furnace and it is needed to withstand the extreme temperatures encountered in melting metals. The crucible material must have a much higher melting point than that of the metal being melted and it must have good strength even when white hot. Graphite crucible can withstand the high temperature, and has good resistance to chemical erosions and thermal shock. Especially graphite crucible is ideal for the melting of aluminum, copper and other metals.

GRAPHITE FOUNDRY FACINGS

Foundry Facing an auxiliary material, such as a paint or paste, used in molding to reduce the tendency of the casting to stick to the mold or core. Paints contain adhesive substances and refractory additives; they increase the surface strength and reduce flaking on molds and cores. Pastes are used primarily as facings for metal molds.

GRAPHITE IN BATTERIES

In traditional zinc-carbon batteries, graphite was simply used for conductivity. For modern portable electronic devices, however, the current standard is lithium batteries, i.e. lithium ion batteries or lithium polymer batteries. In this technology, the use of graphite in batteries serves a more active purpose.

CRYSTAL STRUCTURE

The high surface area and layered crystal structure which are features of graphite makes it suitable for use as an anode material into which the lithium Ions are intercalated. Certain types of battery technology already require graphite to be almost 100% pure. It is very possible that the purity requirements will increase in the future.